Competence

Excellent quality requires continuous progress in metallurgy and manufacturing engineering in various fields of industrial application.

Comprehensive casting and technical services reflect NPA's ability as a global leader in the high-temperature alloy industry innovation.

Research and Development Capabilities

NPA focuses on the technological inovation and industialupgrading of heat resistant aloy.and transforms its scientifc research andtechnology advantages into production and market advantageAt present, 225 patents(including 129 invention patents) were approved and applied to the products and core equipment.

Quality Assurance Capability

Excellent quality requires continuous progress in metallurgy and manufacturing engineering in various fields of industrial application. Comprehensive casting and technical services reflect NPA's ability as a global leader in the high-temperature alloy industry innovation.

NPA focuses on the technological inovation and industialupgrading of heat resistant aloy.and transforms its scientifc research andtechnology advantages into production and market advantageAt present, 225 patents(including 129 invention patents) were approved and applied to the products and core equipment.

Excellent quality requires continuous progress in metallurgy and manufacturing engineering in various fields of industrial application. Comprehensive casting and technical services reflect NPA's ability as a global leader in the high-temperature alloy industry innovation.

NPA Equipment Capability

Flexible multi variety smooth process production, with leading production equipment technology in the industry

By establishing a new production and manufacturing information management system, the coverage rate of automated production lines has exceeded 70%. Following the demands of the international market and the industrialization of new materials, we have introduced automation and digital visualization equipment such as high-purity melting centrifugal casting equipment, gantry trusses, RGV automatic transfer centrifugal pipes, automatic welding, DR, static casting 3D filming; Build an intelligent green factory and strive to achieve the highest level of industry automation and intelligence.

Melting capacity

28 medium frequency furnaces 250-1000kg

1 electric arc furnaces 1500-5000kg

2 vacuum furnaces 500-1000kg

4 baking furnace to dry materials

Centrifugal casting equipment

25 horizontal casting machine

2 vertical casting machines

>800 moulds

Static casting

2 automatic lost wax casting production lines

2 sand mould casting production lines

Machining Facilities

40 boring machines

45 CNC lathes

8 CNC drilling machines

Welding

98 argon arc welding machines

6 welding robots

4 automatic welding machines

Other

8 heat treatment furnaces

14 shot blasting machines

5 3D digital stereoscopic tube benders

Production Methdos

NPA provides a complete set of casting techniques!

Centrifugal Casting

All raw materials using silica sol and zircon powder are dried at 450 degrees before melting to avoid hydrogen corrosion. They are then controlled by PLC and protected by argon gas before entering the casting process. The entire process is used to create components with a very pure and highly compressed structure. The product is free of impurities and is suitable as a first-class high-performance material.

Static Casting

Using a mixture of furan resin, curing agent, and quartz sand for molding, it is commonly used for casting complex large castings and static castings with a wall thickness greater than 15mm. Spraying zirconium powder coating on the mold cavity, high temperature resistance, good surface quality of castings, high mold strength, suitable for producing complex castings with large wall thickness; Sand has good collapsibility, easy cleaning, good molding, low gas generation, good thermal stability and breathability; Reduce casting defects such as sand sticking, sand inclusion, sand holes, porosity, shrinkage, and cracks.

Precision Casting

Using silica sol, zircon powder, medium temperature wax, and mullite sand to make shells, it is mainly used for producing castings with thinner wall thickness, such as twisted sheets and small Y-shaped pipes. High surface smoothness, with a roughness of up to 3.2; The shell has high strength, small deformation of the casting, and high dimensional accuracy. Small and complex casting components with a size range of 25 kilograms and a length of 400 millimeters are best manufactured using precision casting technology. Whether we provide rough or finished products, or ready to use components, this provides extremely good cost-effectiveness.

Supply Guarantee Capacity

Ensure supply, take multiple measures in parallel to ensure delivery time. Actively promote lean management, centralize and intelligently control production progress, procurement logistics, and logistics transportation, quickly respond and solve unexpected problems, and ensure the quality, quantity, and timeliness of supply orders.

Rapid Response

Plan in advance, analyze and control the factors that affect delivery time, such as designing in advance, purchasing barrels and molds, and booking purchased parts, especially imported parts.

Production Schedule Control

The operation control center and the three major business units jointly control the production progress, and the project scheduling specialist tracks and controls the production progress.

Procurement Logistics Control

The project operation department and centralized procurement department jointly control raw materials and outsourcing procurement, plan tracking, and quality control.

Logistics Transportation Guarantee

Logistics team, planning routes; The factory is adjacent to Qingdao Port and Airport, with convenient sea, air, land, and China Europe freight routes.

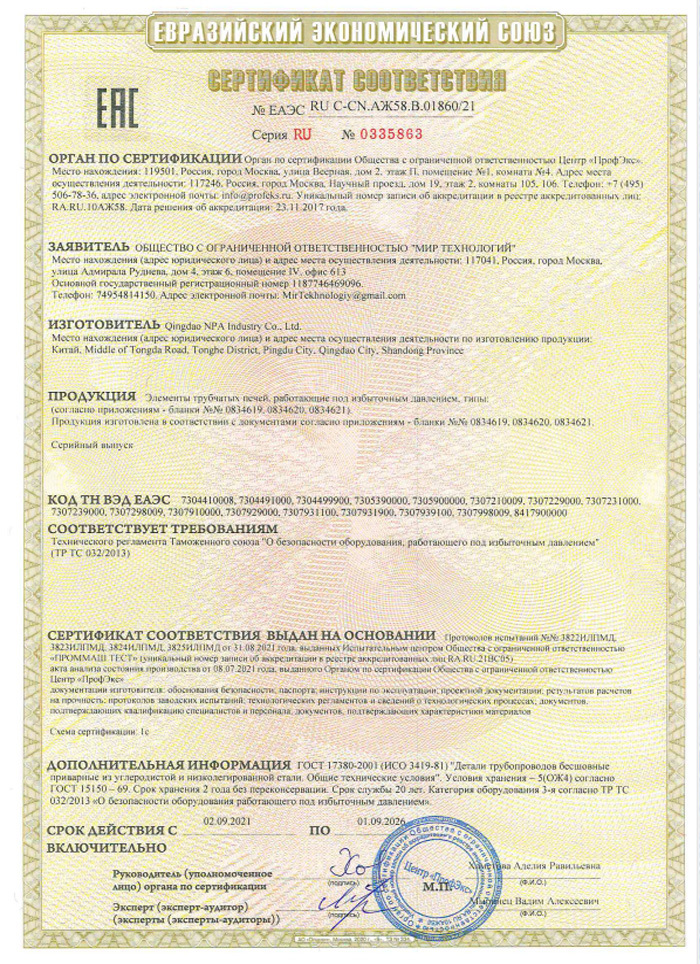

Certification Certificate

All of our factories have passed ISO 9001:2022 certification and always maintain a high level of quality.

We have also obtained ISO 14001:2022 and ISO 45001:2022 certifications from independent experts in the fields of environmental protection and occupational safety.

Tel: +86-0532-87314976

E-mail: npamarket@npa-china.com

ADD: Pingdu High-tech Industrial Park, Qingdao City, China

Copyright © 2023 NPA SEO Business license