Qingdao NPA Industry Co.,Ltd

Qingdao NPA Industry Co.Ltd. is a subsidiary of China iron & Steel Research Institute Group Co. ,Ltd which mainly produces high-temperature alloys with operating temperatures of 900-1250°C, provides integrated solutions of heat-resistant alloy for industrial furnaces around the world, and mainly serves the petrochemical, metallurgy and glass industries to provide ethylene cracking furnace tube and conversion furnace tube, metallurgical production line of various types of furnace, radiation tube, combustion system and environmental protection hazardous waste treatment multi-bed furnace equipment and other products and integration service.

Enterprise Video Display

Scientific research and development projects

Patent applications

R&D personnel

R&D investment

The quality is at the international leading level, with strict system management and comprehensive testing to create high-quality products. All factories have passed ISO9001, ISO14001, and ISO45001 certifications. Efficient standardized processes and information methods, strengthened quality control, integrated supply chain management, greatly improving production efficiency and product quality, providing you with a comprehensive integrated solution.

Innovation leader in the global high-temperature alloy industry

Since its establishment, we have evolved from a high-end application provider to an integrated solution service provider. Nowadays, NPA Company is an innovative leader in the high-temperature alloy industry, with over 770 employees worldwide. We will continue to be customer-centric, with the goal of achieving customer value and unique customer value. Driven by research and development innovation, we are your trusted partner - from consulting to delivery to after-sales service.

We have a strong R&D department that invests heavily in innovative materials, technology, and process optimization. Thanks to close cooperation with renowned research institutions and universities, as well as continuous experience exchange with clients, our research and development ensures sustainable innovation.

01.

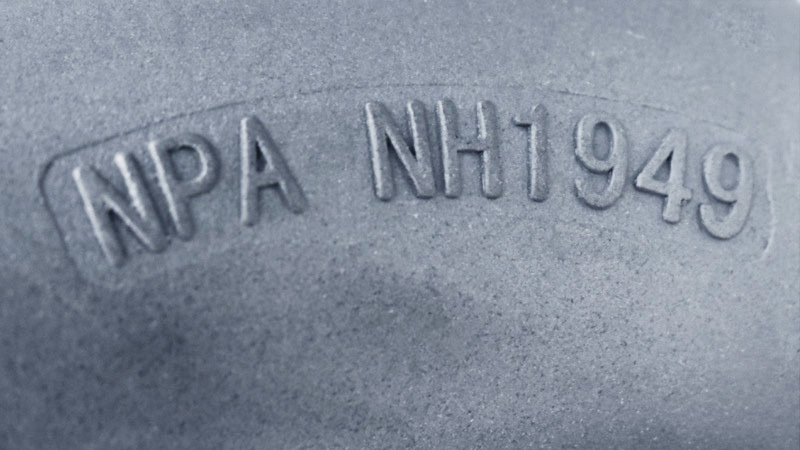

NH1949 Anti coking New MaterialsOur NH1949 high-temperature alloy material can extend the cleaning cycle of cracking furnace tubes in ethylene production, improve production efficiency, and increase service life.

Know More

02.

3D digital three-dimensional pipe bending machineBy relying on advanced industry technology, the entire section of the moderate pipe is directly bent into a U-shaped or S-shaped shape, solving the problem of coking caused by the inability to polish the root of the weld seam.

Know More

03.

R & D capabilitiesNPA focuses on the technological inovation and industialupgrading of heat resistant aloy.and transforms its scientifc research andtechnology advantages into production and market advantageAt present.

Know More

NPA Mainly Produces

NPA mainly serves the petrochemical, steel and glass industries all over the world.

NH1949 Anti coking New Materials

Our NH1949 high-temperature alloy material can extend the cleaning cycle of cracking furnace tubes in ethylene production, improve production efficiency, and increase service life.

NPA provides technical solutions to customers by providing cast static or centrifugal parts, from design to delivery, assembly, finished product and machining.

Global customers trust our products in the field of superheated steam furnaces - from product supply assurance to integrated solution services.

Our casting engineers have over 20 years of casting experience and can design product molds, sprue and riser positions, and forming methods based on different product structural types. And to replace the traditional and complex process confirmation, our factory uses the Huazhu CAE casting process software developed by Huazhong University of Science and Technology for casting process design and confirmation.

Global Integrated Solution Provider of Heat-resistant Alloys Products

1. Full Product Chain

2. Integrated pre-sales, in sales, and after-sales solutions!

Tel: +86-0532-87314976

E-mail: npamarket@npa-china.com

ADD: Pingdu High-tech Industrial Park, Qingdao City, China

Copyright © 2023 NPA SEO Business license